Bubble Deck: a revolutionary method of designing

two-way slab systems in Europe

by:

Mustafa Mahamid

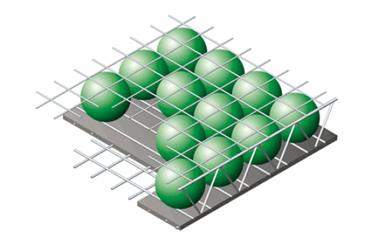

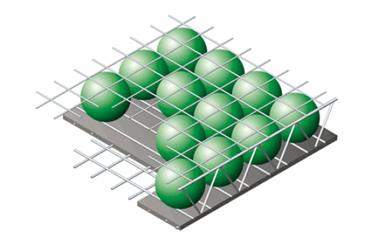

Bubble Deck is a hollow two-way

slab system that has been used in Europe for the last 10 years in lieu of

conventional two-way and one-way slab reinforced concrete slab systems. The

bubble deck system is compos ed

of top and bottom welded steel mesh and hollow plastic ball that replaces the

concrete that has no structural function. The geometry created by the plastic

balls and the mesh width, as shown in the Figure, provides an optimized

statically stable concrete construction with a maximum utility of both moment

and shear zones.

ed

of top and bottom welded steel mesh and hollow plastic ball that replaces the

concrete that has no structural function. The geometry created by the plastic

balls and the mesh width, as shown in the Figure, provides an optimized

statically stable concrete construction with a maximum utility of both moment

and shear zones.

The reinforcing mesh keeps the balls in

exact position while the balls control the level of reinforcing, shape the air

volume, and stabilize the spatial lattice making it ready for concreting to

obtain a two-way hollow slab system.

The main advantage of this

system is in reducing the weight of the structure of approximately 35% that

eliminates the constraints of high dead load and short spans. The weight

reduction results in smaller column sizes and smaller footing sizes, or up to

50% longer spans that result in fewer columns and footings in the building. The

weight reduction also, has a huge impact on earthquake forces and seismic

design.

Punching shear is one of the

major limit states in designing reinforced concrete slabs. Experiments have

shown that shear capacity of bubble deck is 72-91% of the shear capacity of

solid slab and areas of high shear require special attention, therefore the

punching shear issue was resolved by omitting few balls in the critical area

around columns to provide full shear capacity by providing full slab depth

multiplied by the perimeter of the critical section around column to resist

shear forces and moments.

As green credentials are

becoming highly required these days to obtain the LEED certification, this

system may provide some credits due to its contribution to reducing

environmental impact by saving in material up to 50%, using recycled plastic

balls used in the middle of the slab, 1kg of plastic balls replaces 100 kg of

concrete, less energy consumption both in production and transportation, less

emission-exhaust gases from production and transportation, and no waste

generation-100% recycling.

Regarding constructability, the

slab system is constructed by dividing the overall floor area into a series of

individual elements, either 3 meters or 2.4 meters wide. These elements include

the top and bottom reinforcement mesh, sized to suit the specific project. The

top and bottom reinforcement is joined together by vertical lattice girders with

plastic balls to fix the top and bottom mesh in their optimum position. This is

known as “Bubble-reinforcement” sandwich which is then cast into bottom layer of

concrete to provide permanent formwork within part of the finished slab depth.

This is done off-site making it ready to be transported to the construction

site.

On site, a series of individual

elements are placed and stitched together with loose reinforcement across the

joints between the elements. Splice bars are placed above the precast layer and

between the bubbles to connect the individual elements together and prepare the

slab for the final concrete pour.

The bubble Deck system has been

tested in the Technical University of Denmark, Denmark, Technical University in

Delft, Technical University in Eindhoven, TNO, Dycore Verwo, Netherlands,

Technical University of Darmstadt, Germany.

The system has proved to be

highly successful in Europe for the last 10 years, and has been used in Canada

for the last three years.

In the meantime, a local US

consulting firm is investigating the slab system, discussing it with architects

around the country, testing it for UL rating, and in the process of submitting

the technical information to get it certified by the International Code Council.

ed

of top and bottom welded steel mesh and hollow plastic ball that replaces the

concrete that has no structural function. The geometry created by the plastic

balls and the mesh width, as shown in the Figure, provides an optimized

statically stable concrete construction with a maximum utility of both moment

and shear zones.

ed

of top and bottom welded steel mesh and hollow plastic ball that replaces the

concrete that has no structural function. The geometry created by the plastic

balls and the mesh width, as shown in the Figure, provides an optimized

statically stable concrete construction with a maximum utility of both moment

and shear zones.